Does Your Application Require Magnet Assemblies In 2021.

Magnetic materials mention to materials that consists of ferromagnetic substances. They are the prime materials for motors, electrical appliances, electronics, electro acoustics, optics, instrumentation. Magnetic materials can be segmented into soft magnetic materials and hard magnetic materials according to their various properties. This article explains how magnet assemblies work and why they prove to be a common solution for many magnetic applications.

What are the benefits of magnet assemblies?

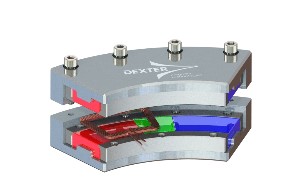

A magnet assembly integrates magnet and non-magnet materials, typically magnetizing them jointly to create a stronger magnetic circuit. The non-magnet materials usually subsume mounting mechanisms for holding applications, while also safeguarding the magnet material from vandalism during use. In addition to this, magnet assemblies offer 3 main advantages:

Increased Mechanical Strength

When deciding on a magnetic assembly, it’s essential to take into consideration that the magnet alloys have an intrinsically brittle composition. Depending on the application, Magnetic Actuators are often exposed to constant mechanical stresses and thus may suffer volume loss. Therefore, causing part of the magnet to chip away from the main body, given rising to a weakening of the magnetic field. To stop this, magnets are mostly blended or integrated with non-magnetic components, such as plastic, ferrous metals, or non-ferrous metals. This produces a protective housing that prevents volume loss. Some common instances of magnetic assemblies include:

- Pot magnets

- Rail magnets

- Channel magnets

Increased Magnetic Strength

Not only do magnet assemblies increase mechanical strength, but they can also contribute to enhanced magnetic strength. When compared to a raw magnet, Ceramic ferrite magnets assemblies often have a higher magnetic force. Simply, the flux conducting elements found in the assembly are an important part of the magnetic circuit. These elements, through magnetic induction, increase the assembly’s field on the region of interest; however, this procedure works best when using the magnetic assembly in direct contact with a work-piece where even the minutest gaps can dramatically impact the magnetic field. These gaps can be an accurate air-gap or any coating or dust which causes a disturbance in the assembly of the work-piece.

Mounting & Special Design Features

Magnetic assemblies can be integrated by a variety of methods; however, most tend to be mechanical. The most familiar type is press-fitting, using a mechanical fastener. Mechanical fastener mounting will also make use of an incorporated tapped or through-hole in the assembly.

Assembly Methods

Magnet assembly producing approaches are as diverse as the materials and Magnetic core material alloys used in them. Hence, there is a range of assembly techniques to suit various applications, including: mechanical assembly, insert molding, over-molding, gluing, heat staking, ultrasonic welding, brazing, and many more.

Does your application require a magnet assembly?

Customers mostly ask whether a magnetic assembly is a cost-effective solution for their application. Depending on if it results in the rise of magnetic performance and part of longevity, a magnetic assembly may be a cost-effective option. The team of experienced engineers can guide you in determining if a magnetic assembly is a viable option.

Source url :- https://sites.google.com/view/dextermagco/home

Comments

Post a Comment